Industrial Engineering Study Program, Faculty of Industrial Technology (FIT) Universitas Islam Indonesia (UII) held an online “sharing session” on Thursday (05/09) with the title “Tips & Tricks to Get Scholarships and Study Abroad.” This event presented one of the lecturers of the Industrial Engineering Study Program at FTI UII, Mrs. Suci Miranda, S.T., M.Sc., as a resource person who will leave for doctoral studies abroad.

A total of 20 participants attended to listen to the sharing session which was held at 13.15 WIB. Putri Dwi Annisa, S.T., M.Sc., was present as the moderator for this sharing session. This webinar began with a resource person who shared her personal data and experience when she decided to continue her studies abroad through the LPDP scholarship route.

LPDP, or Lembaga Pengelola Dana Pendidikan, is a non-echelon work unit under the Ministry of Finance of the Republic of Indonesia that manages education funds in accordance with the mandate of the Minister of Finance Regulation Number 252 of 2010. In addition, Mrs. Suci Miranda also explained how to apply for this program. She emphasized always practicing and trying to get TOEFL and IELTS scores according to the required standards.

Ms. Suci Miranda, S.T., M.Sc., emphasized preparing the necessary document requirements at least a year before applying for the LPDP program. Within a year of preparation, prospective applicants can compile portfolios and achievements to be included in the CV (Curriculum Vitae) as complementary documents.

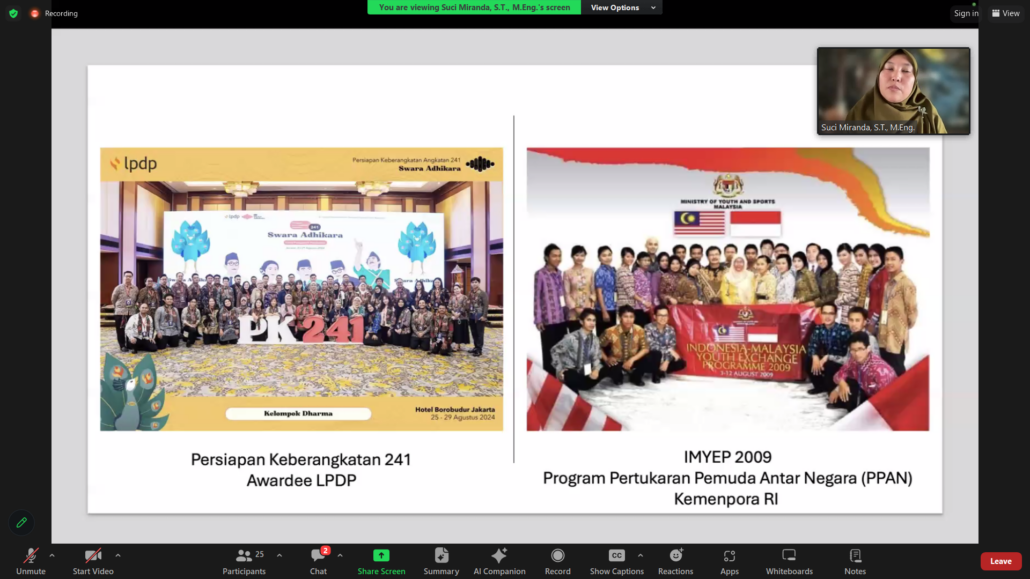

Furthermore, she shared her experience when she joined the LPDP and PPAN programs that supported her master’s studies. This experience became a valuable moment for her to try out various opportunities available, as well as expand her network with students from various countries. “The opportunities that have been given, such as becoming an Awardee or whatever, should be celebrated. Celebrate by making sure that every step, every choice we make will have positive consequences for us,” she said. She meant that every achievement should be commemorated and appreciated.

A question-and-answer session ended this sharing of tips and tricks for winning scholarships abroad. Searching for information from various sources such as websites and social media is key to preparing oneself optimally.

Rani Novalentina