The Industrial Engineering Doctoral Study Program, Faculty of Industrial Technology, Universitas Islam Indonesia collaborated with PT Jasa Raharja Yogyakarta Special Region (DIY) Branch to hold an international webinar on (24/7). The activity carried the theme “Effective Strategies for Increasing Road Traffic Awareness and Reducing Accidents in Yogyakarta” to improve driving safety. The event was opened by Amel Aminuddin as the MC, followed by the reading of the divine words by Pardiya, S.T. The Head of the Industrial Engineering Doctoral Program, Prof. Dr. Ir. Elisa Kusrini, MT, CPIM, CSCP, SCOR-P, hopes that the online event can contribute to helping increase public awareness. “The output of this activity is a strategic academic formulation to socialize traffic safety as an effort to increase the awareness of motorists and pedestrians in the Special Region of Yogyakarta in particular and other cities in Indonesia.” he said.

Furthermore, Muhammad Rizqy Abdurrahman Assyifa as the moderator greeted and invited Regy S. Wijaya, S.Kom, MMSI, AMII, Head of PT Jasa Raharja, Yogyakarta Special Region branch, Indonesia to deliver a Keynote Speech on Yogyakarta traffic accident statistics, such as the number of incidents, casualties, and injuries as the opening session of the international webinar that morning. “The average number of traffic accident victims every day in Yogya is 19 people and the average death toll is 1 victim every day.” he said.

Traffic Culture of Countries in Different Parts of the World

Taiwan

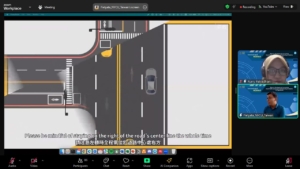

Then, entering the second session, namely the keynote session delivered by several speakers from various parts of the world with moderator Rurry Patradhiani. Fietyata Yudha, S.Kom., M.Kom., who came from National Yang Ming Chiao Tung University, Taiwan explained about the traffic system in Taiwan related to regulations, types of vehicles, and how law enforcement there. “When you are riding a bicycle and there is a pedestrian going through the crosswalk, then you have to wait for the pedestrian to cross first,” he explained. Therefore, a rider should always prioritize pedestrians when on the road.

Florida

Afterwards, the second speaker, Rian Adam Rajagede, S.Kom., M.Cs., from the University of Central Florida, USA shared how the driving culture in Florida strongly emphasizes two important rules, namely stopping at intersections and respecting other drivers on the road. Almost every intersection has a stop sign and drivers are required to slow down to a stop, not just slow down. This also applies even if there is an intersection that does not have a sign, “If there is no sign to stop, the default rule still applies. So, you must stop before entering the intersection.” he said.

Australia

On that occasion, Ir. Muhammad Ragil Suryoputro, S.T., M.Sc., IPM from the University of Wollongong, Australia who also provided experience about the country’s traffic culture. He said that the government wants to realize the transportation strategy of New South Wales, Australia aims to achieve zero fatalities and serious injuries by 2050. “We have Vision Zero targets for 2050, which are safe speeds, limits for speeding areas, promoting safe behavior, and also safe systems.” he said.

Norway

Afterwards, Ir. Andrie Pasca Hendradewa, S.T., M.T., IPM from Norwegian University of Science and Technology, Norway said that the country’s biggest challenge is not the population, but the weather or winter because snow is very disruptive to traffic. Road snow is very dangerous for drivers so the government is always working on cleaning and salting to keep the roads safe. In addition, people also use special tires to prevent slipping while driving. “So, usually people have to change their tires to a type of winter tire that has a lot of spikes.” he explained.

Japan

Meanwhile, Galang Prihadi Mahardhika, S.Kom., M.Kom., from Ibaraki University, Japan talked about 3Es or Traffic Safety System. “So for information, 3Es stands for engineering, enforcement, and education, one of several approaches that can be used to develop traffic safety.” he said. Examples of the application of engineering can be in the form of road improvements, enforcement in the form of sanctions for traffic violators, and education in the form of road safety campaigns.

The last keynote speaker, Ir. Ahmad Padhil, ST, MT, IPM, ASEAN Eng from Universitas Islam Indonesia, Indonesia, talked about ways to avoid traffic accidents. It starts with identifying the factors that cause incidents, such as lack of regulations, lack of facilities, lack of awareness, and especially lack of compliance. “If someone has awareness but does not comply, there are regulations, there are facilities, it will not work. Traffic compliance refers to the act of following traffic rules and regulations set by the relevant authorities.” he said.

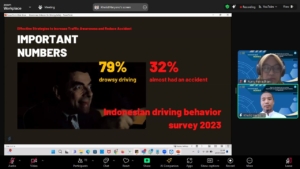

Drowsiness Detector for Driving Safety

The last session was an explanation of the research of Zainudin Zukhri, S.T., MIT and Kholid Haryono, S.T., M.Kom., from the Islamic University of Indonesia, Indonesia regarding the creation of drowsiness detectors due to the many accidents that occur due to microsleep. The implementation of drowsiness detection technology and supporting traffic regulations can help reduce road accidents. “There are four expectations from the drowsiness detector. First, it warns drivers about drowsiness and the risk of microsleep, helps avoid accidents caused by fatigue, gives other drivers the opportunity to avoid collisions, and forces drivers to take the best action.” he explained. Afterwards, a question and answer session with all the speakers was held to finalize the international webinar on increasing driving awareness and safety.

Audiamara Vinka