Industrial Engineering UII Organizes Lean Public Lecture

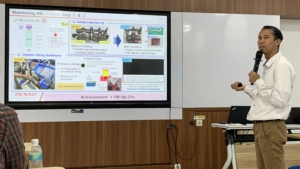

In order to deepen the practical knowledge about lean, Industrial Engineering of Universitas Islam Indonesia (UII) held another public lecture entitled “Lean/Total Industrial Engineering Basic, Standardized Work & Low Cost (Automation) Improvement”. The event invited an alumni who currently serves as Kakaricho Dept Manufacturing Engineer & TIE at PT Denso Manufacturing Indonesia, namely Nur Kholiq, S.T. The morning activity was held on Saturday (4/5) and took place in Classroom 2.14 FTI UII which was attended by 22 UII Industrial Engineering Students. Nada Putri Fauziyah as the MC began by inviting Putri Dwi Annisa, S.T., M.Sc., Representative of the Industrial Engineering Study Program to describe her remarks. She said that this agenda was a collaboration from last year.

“Well, this year is the continuation. The material will be a little different maybe. Hopefully it can be useful.” he said.

Lean/Total Industrial Engineering Basic

Next, the material was presented by Nur Kholiq, S.T., about the Basic Production System in Automotive, namely the Toyota Production System (TPS) which has 3 pillars in the form of Just In Time, Jidouka, and Abnormality. Toyota Production System (TPS) is a production system that aims to eliminate waste in order to achieve efficiency. This system applies the profit concept of monopoly era, local competition era, and global competition era.

“Pertalite may disappear next month with the existence of Pertamax, will we buy it? We will. Regardless of the price we still buy, that’s the monopoly era. Second, local competition era. So, to increase the profit, we reduce the cost. For example, the price is the same because if the price is not the same, the market people fight. The last one is the global competition era. We lower the cost, increase the profit, but still below the previous price,” he explained.

Then, there is the term Mura Muri Muda, which means that an irregularity will burden a job and causing a waste. This waste is all work that does not value added product. Thus, when there is waste, the resulting production costs are higher.

Standardized Work

The next material is about standardization in a job. Kholiq said that there is written and unwritten standardization. Written standardization is a standard that has been standardized by each company. Meanwhile, unwritten standardization is a standard that has been considered a culture. In addition, there are three important factors in work standards, namely takt time, work order, and standard stock in the process. All three will affect the occurrence of overtime and idle time.

Low Cost (Automation) Improvement

Finally, there was material on low cost automation using the Karakuri Kaizen concept. Karakuri Kaizen is an approach to material management that utilizes the force of gravity, the use of levers and hinges, and utilizes the principle of inertia to move goods. The advantage of principles from the Land of Sakura can reduce working hours and costs that the company produces. One of the implementations of this concept is in the process of moving empty boxes manually which then changes to utilizing a spring so as to minimize waiting time. Meanwhile, a group photo between the speakers and participants was the closing session of the public lecture agenda on this lean concept.

Audiamara Vinka