The Industrial Engineering Study Program, Faculty of Industrial Technology (FTI), Islamic University of Indonesia (UII) is once again holding its annual Industrial Engineering Creativity and Gathering Event (AKSI TI) 2025. The event will take place over three days, on December 14, 2025, and December 20–21, 2025, at the FTI UII Auditorium and Girikaton Campground.

AKSI TI 2025 carries the theme “Sailing in Harmony Towards the Port of Mahardika” as a symbol of togetherness in welcoming new students. This year, AKSI TI presents a different atmosphere with the participation of new students from the Engineering Management Study Program, which was officially opened in the 2025/2026 academic year and is still under the same department as Industrial Engineering.

Over 100 new students from both programs participated in the event. Through AKSI TI 2025, the organizing committee aimed to introduce the department environment and foster solidarity and a sense of community from the very start of the academic year.

Udaya Day

The FTI UII Auditorium was the venue for the first day of AKSI TI 2025. The Opening Ceremony kicked off the series of activities with remarks from Bama as Chair of the AKSI TI 2025 Organizing Committee, Muhammad Arief Dzikri as Chair of the AKSI TI 2025 Steering Committee, Bayu Maulana as Chair of HMTI LEM FTI UII 2025/2026, Ir. Muhammad Ridwan Andi Purnomo, Ph.D., IPM., as Head of the Industrial Engineering Study Program, and Elanjati Worldailmi, S.T., M.Sc. as Head of the Engineering Management Study Program. The event was officially opened with the striking of a gong.

On the first day, the committee also introduced the Industrial Engineering Student Association (HMTI LEM FTI UII) as a student organization. In addition, participants attended a seminar with Industrial Engineering alumnus Vicky Caneca, S.T., MBA, as Chief Executive Officer (CEO) of MyMedica.id. The series of activities was complemented by a session sharing experiences from seniors and alumni, as well as an introduction to the laboratory through the Lab Show event.

Madhya Day

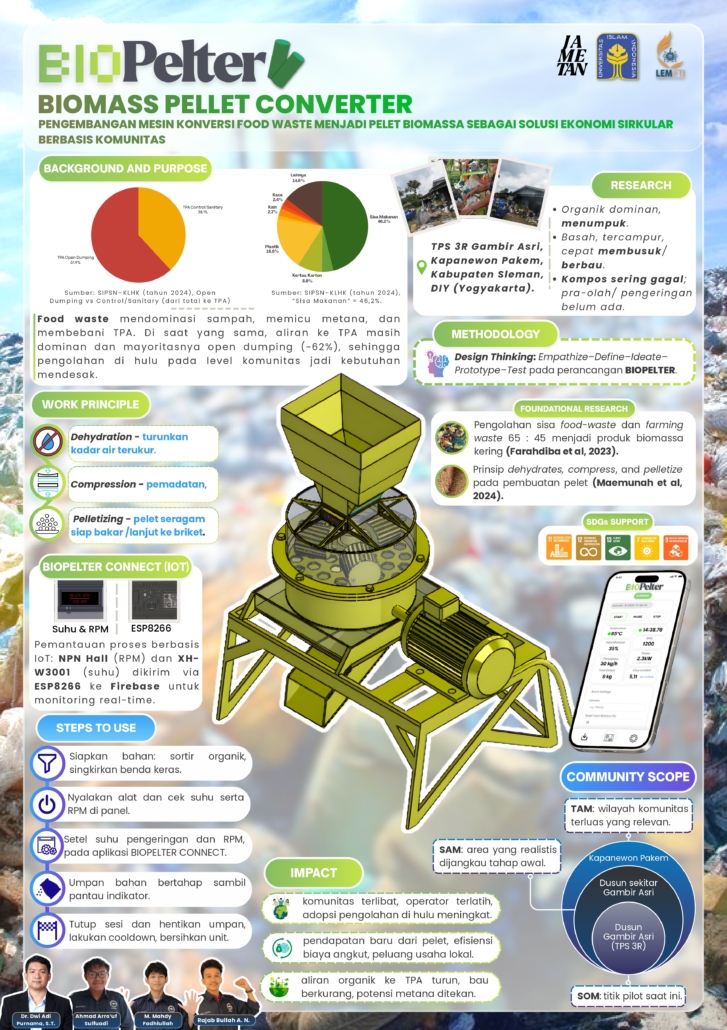

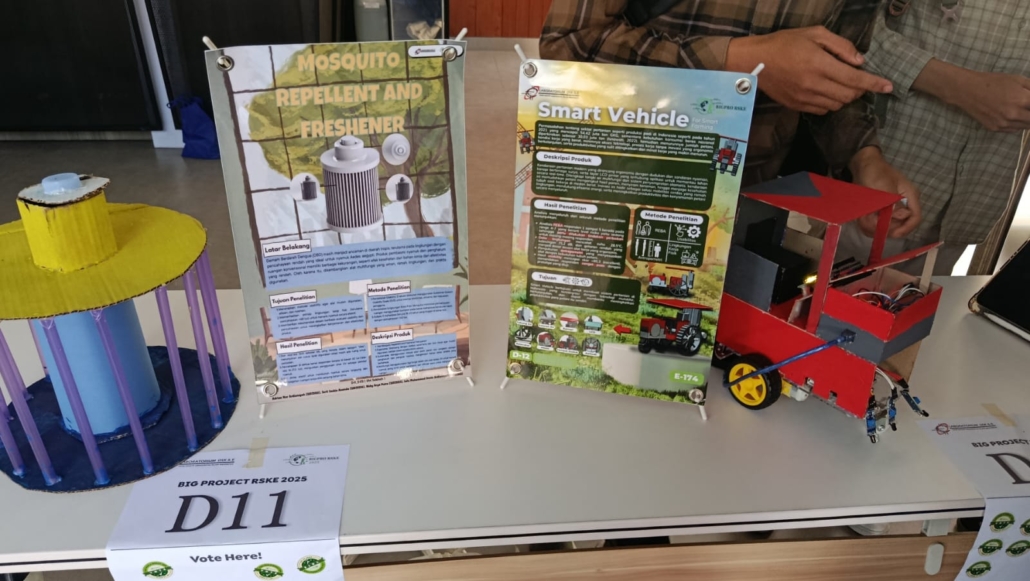

The second day of AKSI TI 2025 took place at the Girikaton Campground for two days and one night. Participants took part in a fun camp with various activities that encouraged creativity and togetherness. One of the main agendas was to assign each group to design an innovation prototype, while representatives from each laboratory assessed the results on the last day.

A solemn atmosphere was present during the Inauguration event, when new students took the student oath together. The Chair of HMTI LEM FTI UII led the oath and presented HMTI uniforms as a symbol of welcoming new students into the HMTI LEM FTI UII family. The second day’s activities ended with a Rhythm Stage performance by Imunity Band.

Wasana Day

On the last day, participants will explore obstacles to reach seven available posts. The event Ngolah Otot Santai (Ngosan) or group exercise will start the day with a fun exploration to train teamwork among group members. Before going down to explore the Jelajah Asik Teknik Industri (Jejak TI) event, participants will have breakfast together first.

The Closing Ceremony concludes the AKSI TI 2025 event, with the Chair of the OC, SC, HMTI, LEM, DPM, and Activity Coordinator Dian Janari, S.T., M.T., delivering their messages and hopes. As a symbolic gesture, a gong is struck to mark the end of AKSI TI 2025. The event concluded with the screening of an After Movie summarizing all the moments from Udaya Day, Madhya Day, to Wasana Day.

To conclude the AKSI TI 2025 series, the Chair of the AKSI TI 2025 Steering Committee, Muhammad Arief Dzikri, shared his impressions and messages regarding the implementation of this event. He considered AKSI TI 2025 to be a memorable and meaningful experience, not only as a department orientation activity, but also as a forum for instilling the values of togetherness and kinship.

“AKSI TI 2025 has been a very memorable experience for me. This event was not just an orientation for the department, but also instilled many values in each series of events. Alhamdulillah, all activities were well organized, ran smoothly, and were able to build a sense of solidarity and kinship between new students and the committee,” said Arief.

He hopes that AKSI TI can continue to grow and present fresher concepts in the coming years.

“Hopefully, AKSI TI in the future can be organized better, more innovatively, and creatively, and remain a memorable story in the future. Because Great Stories Are Made by Us,” he concluded.

Rani Novalentina