On Saturday (24/08), the Doctor of Industrial Engineering (DRI) Study Program at the Faculty of Industrial Technology (FIT) Universitas Islam Indonesia (UII) successfully held its first sharing session. Featured the Head of the DRI UII Student Association, Dr. (cand). Ahmad Padhil, S.T., M.T., IPM., ASEAN Eng., as speaker, the sharing session talked about Tips and Tricks for S3 Study at Doctor of Industrial Engineering, FTI UII. This activity took place online through a zoom meeting with 28 participants participating in it.

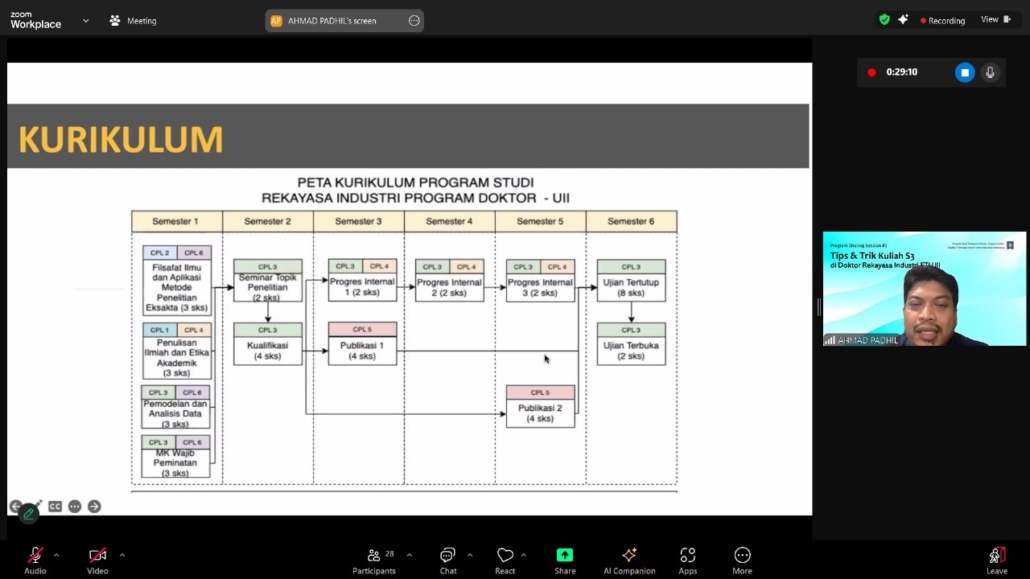

The event began at 09:00 WIB, with the MC greeting the participants enthusiastically. Following a quick introduction by the MC, the event moved on to the main agenda, which was the material delivery session. In his presentation, Ahmad Padhil discussed several aspects related to the scheme and life of S3 lectures at DRI FTI UII, ranging from the curriculum, the number of credits, and the activities.

“In terms of aims and systems at UII, the Industrial Engineering Doctoral program’s courses are divided into progress activities that we will accomplish. This period lasts from the beginning to the end, which is the sixth semester”, he stated, starting off a conversation regarding the flow of lectures and numerous activities throughout the semester.

Furthermore, he went through the S3 lecture method at DRI FTI UII, which offers numerous benefits to students. One example is the attendance system, which is integrated with UII Connect and allows students to fulfill academic commitments without needing to be physically present on campus. This allows for more flexibility and support for students who have structural responsibilities and other duties during the lecture session. Additionally, doctoral students have access to campus residential. DRI FTI UII also actively hosts and participates in a variety of activities, including competitions, international webinars, and collaboration with external organizations.

“Alhamdulillah we have a considerable number of activities at DRI. Even though we work online, when we do get to Jogja, those activities can be carried out productively and to the fullest,” he said.

As the Q&A session began, Ahmad Padhil, a member of the first cohort of DRI FTI UII students shared study tips by answering questions from the attending academic peers. The sharing session event ended with a group photo session.

Syawarani Gayatri