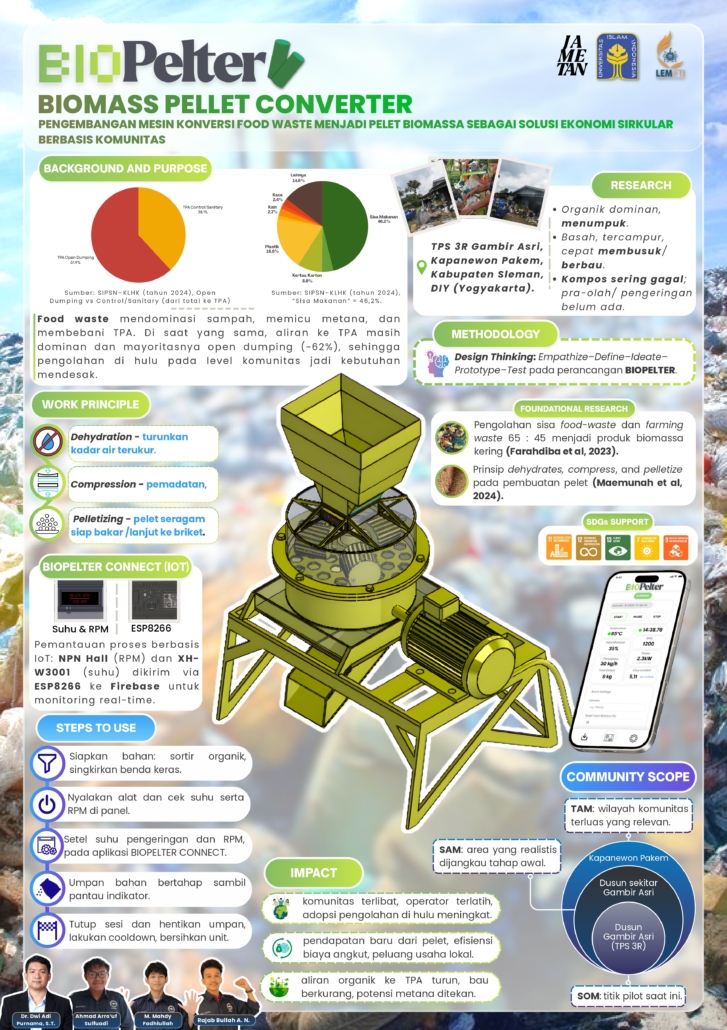

Yogyakarta, November 30, 2025 – Sang Adji Paco Labib, Afiana Saputri, and Pradita Nur Maulidina, Students of the Industrial Engineering Study Program, Faculty of Industrial Technology, Universitas Islam Indonesia participated in the Industrial National Competition (INCO) 2025, a national level competition. The event was organized by the Industrial Engineering Student Association of the Faculty of Industrial Technology, Universitas Muslim Indonesia (UMI), and was held from November 28 to 30, 2025. INCO 2025 involved students from various universities across Indonesia. The competition carried the theme “Sustainable Product Design Innovation for Human Well Being and Optimal Ergonomics.” Through this competition, students presented environmentally friendly and ergonomic product design ideas. The event aimed to encourage innovation that balances human needs, environmental sustainability, and economic value.

INCO 2025 Strengthens the Role of Students in Industrial Design Innovation

To support the objectives of the competition, the INCO 2025 organizing committee designed the competition stages in a structured and systematic manner. Participants began the competition by registering and submitting abstracts of their scientific work. After passing the abstract selection stage, participants proceeded to prepare and submit full papers, which included complete proposals, product designs, and posters. The committee then selected the finalists and conducted a technical meeting to prepare for the final stage. During the final round, finalists presented their product ideas directly in front of the judging panel. The evaluation process emphasized innovation, sustainability, and the alignment of the designs with ergonomic principles.

“Do not hesitate to try and participate in competitions, even if you feel that you are not fully prepared. The preparation process and the experience gained are far more valuable than the final result. With the willingness to learn, collaborate, and step out of your comfort zone, participating in competitions can become a very beneficial means of self-development,”Dita said.

During the competition period, participants organized their preparation through discussions, literature reviews, and structured task allocation. The team managed their time consistently to keep competition activities aligned with academic responsibilities, while open communication helped team members combine different ideas and viewpoints. Through this process, participants gained valuable experience in a national level competition. In addition to enhancing critical and creative thinking skills, participation in INCO 2025 also expanded professional networks and fostered motivation to continue innovating.

Kaila Bilbina M.S